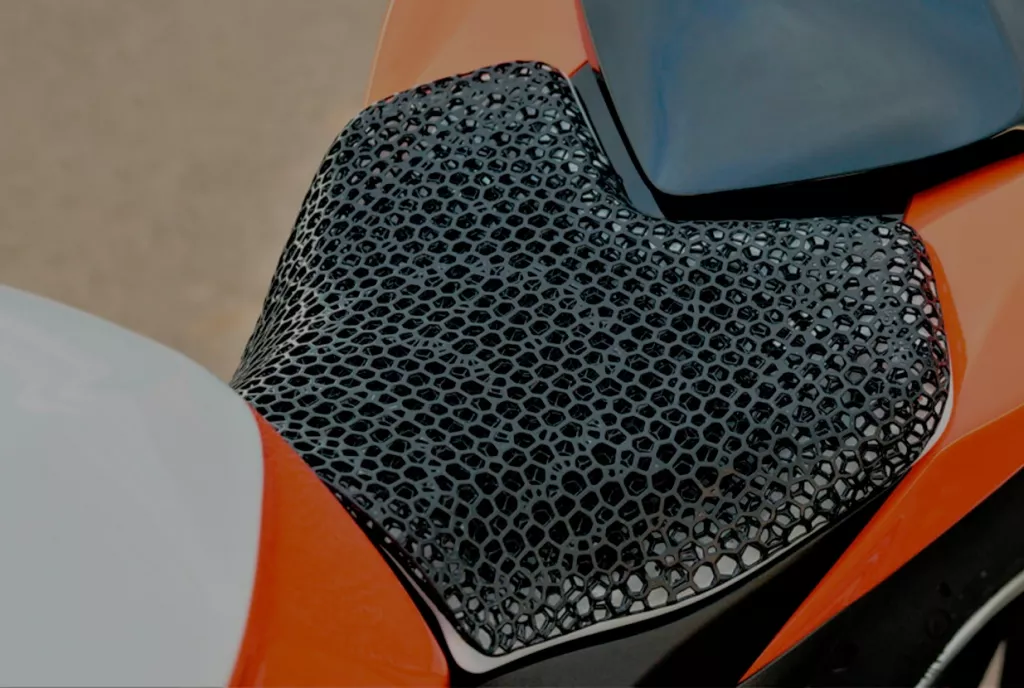

"The motorcycle saddle is a core interface between rider and motorcycle. Additive Manufacturing enables us to go beyond the limits of conventional materials and manufacturing processes, and deliver greater comfort and safety." - Max Lehnert, Program Manager AM Lattice, OECHSLER.

- Assembly

OECHSLER’s Electric Parking Brake - Success story

We provide sophisticated solutions, based on 20 years of experience in actuator development, prototyping, and manufacturing.

Mehr erfahren