- Assembly

OECHSLER’s Electric Parking Brake - Success story

We provide sophisticated solutions, based on 20 years of experience in actuator development, prototyping, and manufacturing.

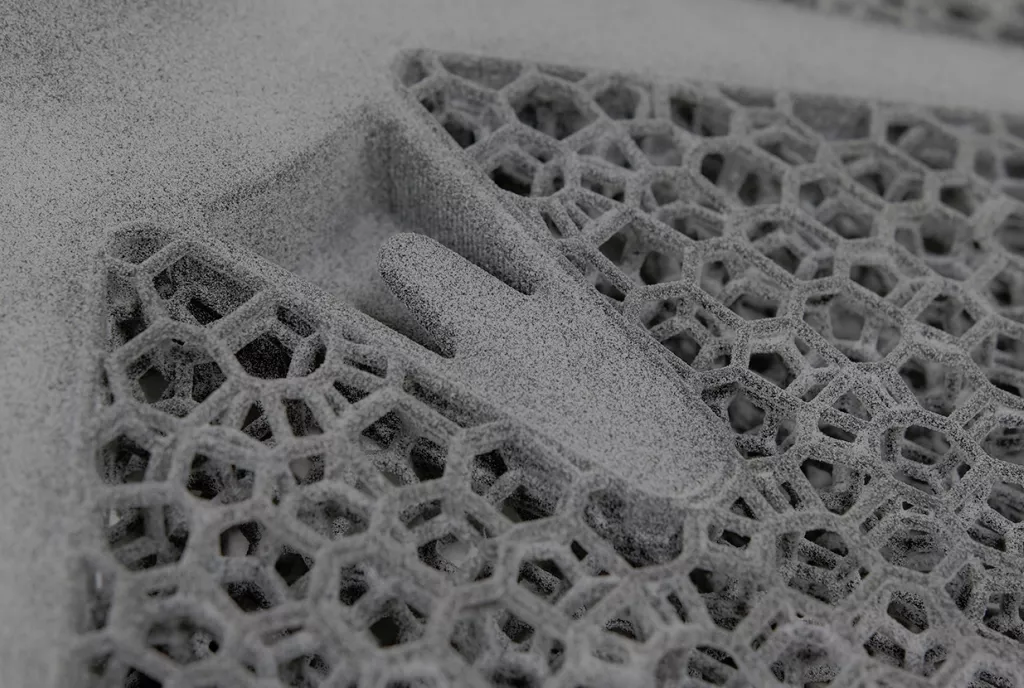

Learn moreAdditive Manufacturing has enabled two industry-breaking product categories at OECHSLER: 3D printed solid parts offer the production of complex geometries. Open cell structures – called “Lattice” – substitute cushioning solutions, and can be individually designed to customer needs and applications. Combining our expertise in a cross-manufacturing approach, OECHSLER offers hybrid solutions, integrating solid and lattice into one product.

OECHSLER leverages Additive Manufacturing to produce highly complex, even bionic solid parts. Those stand out for their complexity in merging several components into one. Designing a part for 3D-printing, therefore, reduces assembly needs, lower tooling investments, and shortens tolerance chains. Our solid parts are already implemented in real-life applications across different industries.

The starting point for our lattice development is usually a CAD model featuring a solid component with a fixed outline geometry. An algorithm transfers this geometry into a lattice structure, which is then optimized by one of our highly experienced engineers according to customer specifications such as compression strength, strut thickness, height, and geometry. Since each strut can be assigned parameters, we enhance stability or cushioning precisely where needed.

Lattice structures provide unlimited design freedom regarding cell structure, geometry, volume, strut size, and compression. Individualizing these parameters for any application and customer requirements enables innovative product applications.

The lattice structure is characterized by apertures between cells and layers, allowing for significant weight reduction while maintaining structural integrity. The effective distribution of material enables the development of lightweight solutions for various industries.

Open lattice structures by OECHSLER feature an air-permeable comfort layer that increases breathability and ventilation. This reduces the temperature and relative humidity rise at pressure points significantly.

Lattice structures can be modified to realize damping effects by the design of the geometry, size, thickness of struts, material, and technology. The properties then manage the absorption of energy from linear and rotational impacts and can be applied in prevention or protection products.

Lattice structures can be modified to realize energy recovery by the design of the geometry, size, thickness of struts, material, and technology. The lattice structure manages to absorb energy and return it. We have applied this to the development of midsoles to transform a vertical force into a forward motion when running.

The design freedom of the struts provides the flexibility to implement varied hardness degrees in one part based on different pressure areas. The design is adjusted to the required application and increases comfort, ideal weight distribution, and unprecedented levels of customization.

OECHSLER has built extensive testing capabilities at our Additive Manufacturing hub in Brodswinden. Whereas testing for solid components is comparable to our injection molding parts, we have designed new testing procedures for our lattice structures, including compression hardness, continuous stress, energy absorption, and heat dissipation.

Markus Bischoff

Senior Vice President Sporting Goods & Additive Manufacturing

3dprinting(at)oechsler.com

Markus Bischoff

Senior Vice President Sporting Goods & Additive Manufacturing

3dprinting(at)oechsler.com