Outcome

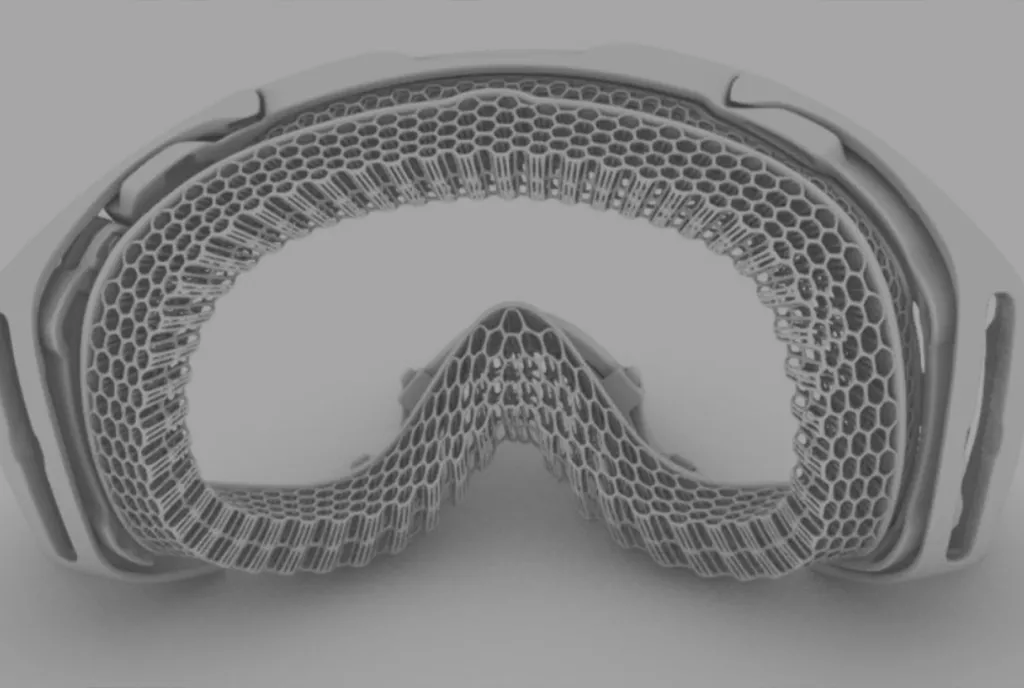

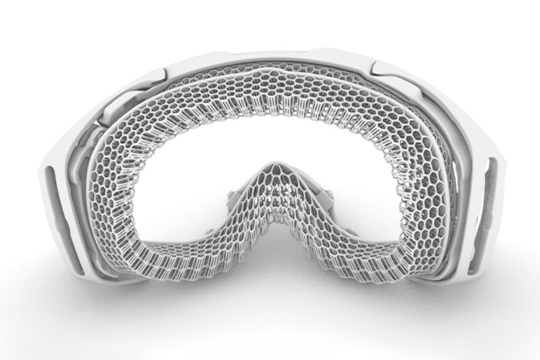

The additive manufacturing lattice technology enables a variety of comfort and design applications that have not been possible before. Additionally, the rapid development and production process enables a start-to-finish product timeline of around four weeks. The example of the additive manufactured skiing goggles shows the following advantages that can be applied to multiple products as well:

- Increased wearing comfort and integrated damping function in case of an accidents

- Combination of rigid and soft elements in one component

- Movable joints instead of extra parts like clips

- Reduction of material variety leading to easier recycling at the end of the product life cycle

- Reduction of production costs due to the elimination of mounting steps

- Foam replaced by 3D printed lattice structure: adjustable hardness – the existing multi-layer foams can be replaced