Outcome

In the spirit of "Moving Beyond Innovation", OECHSLER and Sneakprint have successfully launched sneakers featuring custom 3D printed midsoles. While Sneakprint is a unique blend, leveraging 3D printing technology and skilled craftsmanship to create custom-fit shoes from responsibly sourced leather, OECHSLER’s Additive Manufacturing technology ensures exceptional comfort tailored to individual needs.

All product benefits at a glance:

- Customized shoes that offer unparalleled comfort

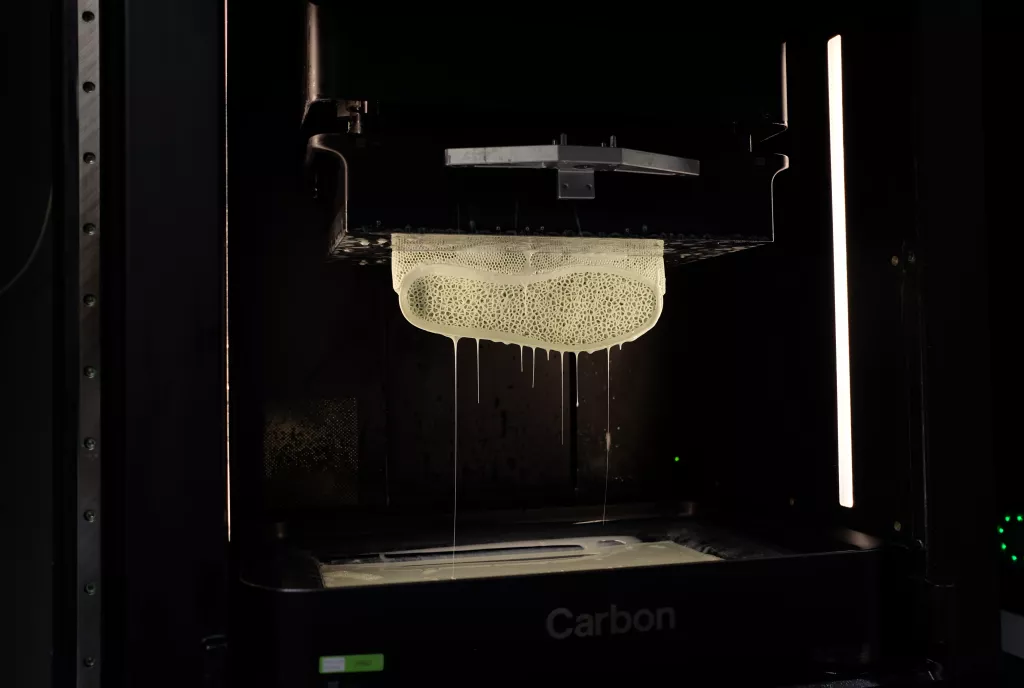

- Lattice structures in the midsole to provide optimal cushioning and support

- Dynamic and durable EPU 41 material to increase longevity

- Quick and efficient creation of intricate custom designs through DLS

- 3D printing enables the recycling of excess material