What our customers say:

"The focus on energy efficiency and carbon footprint exactly meets the pulse of the times."

OECHSLER is constantly working on more sustainable products and has therefore redesigned professional track spotlights. Building on our polymer expertise and high quality standards in automotive and healthcare, we have replaced a relevant aluminum content in high lumen output spotlights with heavy duty plastics. e³ is designed to minimize eco-footprint and maximize efficiency, while maximizing light quality. We thus offer innovative thermal management and significantly reduce the eco-footprint both during manufacture and over the entire lifetime. Thanks to its minimalist and modular design, it allows e³ to be integrated into any architectural space and is ideal for shop/retail applications.

What our customers say:

"The focus on energy efficiency and carbon footprint exactly meets the pulse of the times."

e³ - sustainable lighting is your luminous solution for reducing carbon emissions in production and due to energy saving over livetime.

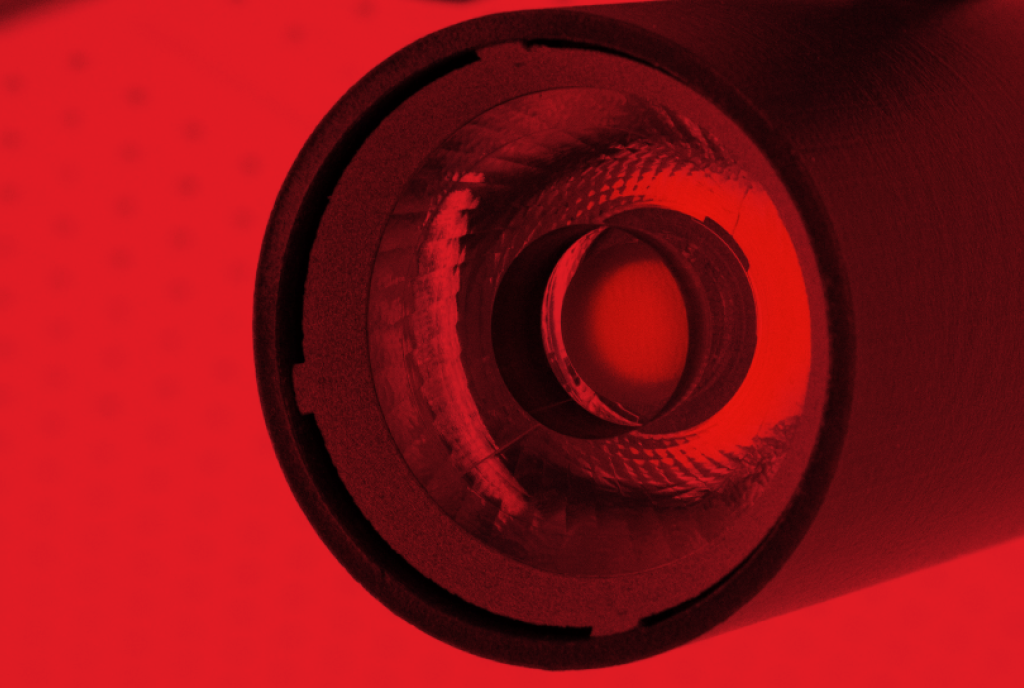

The light from our OECHSLER hybrid optics is more focused. With the same lumen output, the core light has up to 70% higher illuminance on the target object compared to the reflector spotlight, making it appear more vivid and sharper. The CRI value is always greater than 90 so that the goods are illuminated optimally and naturally. The light distribution is very homogeneous with focused illuminance in the core light. The transition from the core light to the peripheral area and the dark area is soft, without a hard edge. Alternatively, the higher illuminance in the core light can be used to further reduce the power consumption of the lighting system, or at least in part. The reflector spotlight produces a relatively hard shadow edge - a "flashlight effect". With the lens, the light curve is much more harmonious.

The e3 power track spotlight Made-in-Germany combines sustainable design, smart technology and unparalleled illuminance. For our customers, this results in a high-performance product with a harmonious light pattern, where energy can be saved significantly. With its leading expertise in polymer solutions, OECHSLER offers the highest product quality, a reduced CO2 footprint in manufacturing and resilient supply chains within Europe.

e3 Power Track Spotlight Made-in-Germany

*The market launch and marketing of our e³ spotlight in Europe and South America is carried out exclusively via our distribution partner Brighthub GmbH and its sales partners to commercial B2B customers. Just like us, Brighthub is committed to sustainable and future-proof lighting products. If we have aroused your interest as a commercial user, we are pleased and ask you to contact Brighthub with confidence. If you are an experienced dealer in the professional lighting market or a provider of professional lighting solutions and are interested in marketing e³, please also contact Brighthub GmbH with confidence.